Drum brakes are a type of mechanical braking system that uses friction caused by a set of shoes (a.k.a brake shoe) that presses outwards against a rotating brake drum. These brakes need regular adjustment of brake wire and brake lever adjustment. They also require frequent changing of shoes at a particular period of time after usage.

In this braking system, the action happens inside a cylindrical-shaped drum thus, giving it the name ‘Drum Brake‘.

However, these brakes are generally operated with mechanical force by brake pedals but in some other applications, they were also operated by hydraulic force mechanism.

However, Drum Brakes are only used in less-priced bikes and scooters. But earlier, only performance bikes up to 250ccs were available with rear drum brake as an option and with disc brakes on the front again for keeping the prices low.

In the 1900s and earlier times, they were used in cars and heavy vehicles. But with changing technology and the availability of better capability of braking power they are not used on modern cars, trucks, and performance bikes. However, we might find old-age cars and trucks with drum brakes.

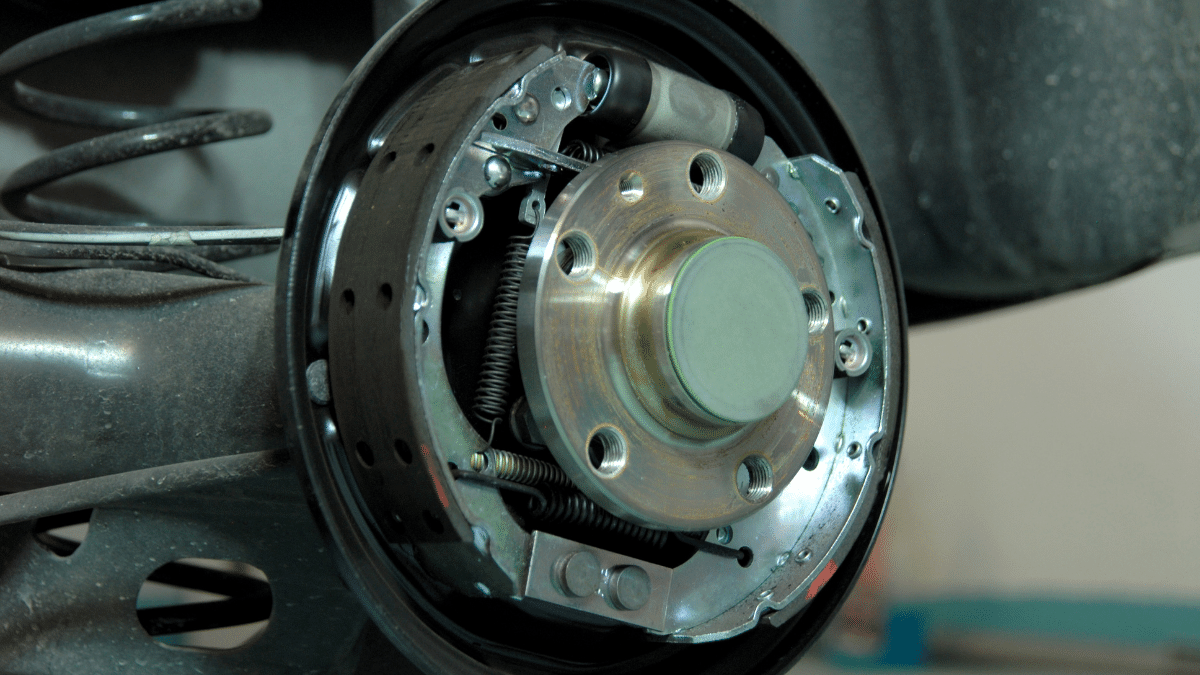

Main Parts of Drum Brakes

Brake Drum

It is a hollow cylinder shaped structure in which the braking action occurs. It is the outermost part of the drum brake that is attached to the wheel rim and rotates along with the wheel. The brake drums are usually made of nickel-iron castings, iron, and steel castings, etc.

Brake shoes

It carries the brake lining and is present inside the brake drum. When the brake is applied this brake shoe comes in contact with the drum.

Brake linings

It is the consumable part of the drum braking system, which means more wear is caused on the linings. They are hard material because they are rubbed against the drum. It is attached to the brake shoe with the help of rivets or by cementing.

Cam / Toggle lever / Expander

It is a mechanism that slides or moves the brake shoe towards the brake drum. It is the first part of the drum braking system which executes the force and forces the shoe towards the drum. The toggle lever is connected to the brake shoe.

Retracting spring

It is the spring that retracts the shoe in its original position to keep no contact between the drum and lining shoe after braking action.

Working of Drum Brakes

When the brake pedal or lever is pressed, the toggle lever/cam turns which forces the brake shoe to move away, and consequently, it makes surface contact with the brake drum. As a result, the brake lining mounted on the brake shoe comes into contact with the brake drum, and friction is produced. This friction slows down the wheel.

As soon as the brake pedal is released the retracting spring forces the brake shoe to come back into its original position. Thus, the surface contact between the lining shoe and drum is over and now, the wheel is free to rotate.

Generally, the braking in drum brakes is caused by the brake pedal force and consequently, the linkage transmits the pedal force to the brake shoe. More the pedal force within the usable range, more is the braking action. However, beyond the usable range, the linkage might break off due to impact energy.

Applications

- Low cost and small cc bikes or scooters (50-125 cc) to keep the cost of product low.

Advantages

- Brake shoes and other replaceable parts are cheap and easily available.

- Simple design.

- Adjusting and installation of brakes are easy.

- Anyone who has experience in bike riding can adjust the brakes without the help of a mechanic.

Disadvantages

- Drum brakes don’t dissipate heat like disc brakes.

- Less powerful and stopping distance is more. Nowadays, there are more advanced brakes like hydraulic brakes and air brakes.

- When water comes in contact with brakes it makes scratching noises and the braking becomes less effective after 2 or 3 times of usage.

- When the drums are heated by hard braking, the diameter of the drum increases slightly due to thermal expansion. So, the shoes must move farther and the driver must press the brake pedal farther.

- Only used for low-cost and light applications like small bikes (50-125 cc). They can’t be used in cars or trucks because the speed and weight of the vehicle are high and during braking, any part may break.