A hydraulic brake system is a braking mechanism that uses liquid pressure or oil pressure (transmitting from a controlling mechanism to the braking mechanism) to slow down or completely stop the vehicle.

In simple language, hydraulic brakes use oil pressure for braking action. Here, you will learn about the hydraulic brakes working, principles, advantages, and disadvantages.

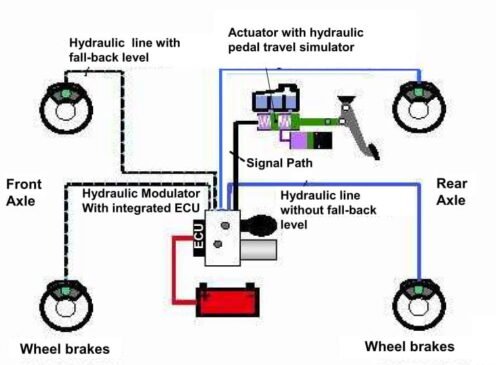

Hydraulic Brakes Components

The main parts of hydraulic brake system are:

1. Master Cylinder

The master cylinder or master brake cylinder converts the brake pedal pressure to hydraulic pressure by transmitting brake fluid into the brake circuit and controlling this according to the mechanical force. Disc Brakes and Drum Brakes, both use a master cylinder.

2. Brake Lines

Brake lines are tubes that carry fluid between brake components. Brakes translate the pressure from your foot on the brake pedal into stopping power.

3. Brake Pedals

The brake pedal to press with your foot in order to make a vehicle go slower or stop accordingly with respect to the force applied.

4. Braking action by Disc/Drum (Near wheels)

Different types of brakes (Disc and drum) slow down the vehicle by the hydraulic pressure of oil or fluid which is directly applied to the wheel brakes.

5. Wheel Cylinder in Hydraulic Brakes

It is a different cylinder than the master cylinder. It is the cylinder of the wheel. Located in each wheel. Its function is to exert force onto the shoes so as to bring them into contact with the drum and stop the vehicle with friction.

6. Brake Fluids

The common brake fluids used in hydraulic brake systems are DOT3, DOT4, DOT5, etc. For instance, DOT3 DOT4 and DOT5 are glycol ether-based which generally means that they absorb moisture from the atmosphere.

However, liquid pressure helps in the application of hydraulic brakes. The transmission of pedal force to the brake shoe with the means of a confined liquid through a system is brake fluid. The force applied to the pedal multiplies and transmits to all the brake shoes by a force transmission system.

The Force Transmission system is based upon Pascal’s principle, which states “the confined liquids transmits pressure without loss, equally in all directions.”

Essentially there are two main components, the master cylinder, and the wheel cylinder. The master cylinder is connected by tubing to the wheel cylinders at each wheel. The system is filled with light pressure when the brakes are not in operation. However, the liquid is known as brake fluid.

Each wheel brake consists of a cylinder brake drum mounted on the inner side of the wheel. The wheel brake revolves with the wheel but two brake shoes mounted inside the brake drums do not rotate. The brake shoes consist of heat and wear-resisting brake lining on their surfaces.

Hydraulic Brakes Working

The brake pedal is connected to the master cylinder piston by means of a piston rod. When we apply brakes or when we press the brake pedal, the piston forces into the master cylinder, which increases the pressure of fluid inside the master cylinder and in the entire hydraulic system. This pressure goes to the wheel cylinders on each of the four brakes, where it forces the wheel cylinder pistons outwards. These pistons, in turn, force the brake shoes out against the brake drums.

When we release the brake pedal, the master cylinder piston returns to its original position due to the return spring pressure. Thus, the fluid pressure inside the entire system drops to its original low value, which allows retracting springs on wheel brakes to pull the brake shoes out of contact with the brake drums into their original positions. This causes the wheel cylinder pistons to come back to their original inward position.

Thus, the braking mechanism is complete.

Applications

The hydraulic brake system is widely mostly in cars or automobiles and is one of the most important applications. It is more efficient than the air brakes that were used earlier.

Advantages

Here is a list of some most important advantages of hydraulic brakes.

- They transmit uniform pressure. (Due to hydrostatic pressure being equal in all directions, Pascal law).

- They help in multiplying the driver’s effort more times than that of Mechanical Brakes. (Hydraulic leverage ratio, hydraulic advantage). Higher mechanical advantage.

- The brake fluid also acts as a lubricant and reduces the frictional losses at high-speed braking.

- They are simpler in construction and lighter in weight.

- Thermal stresses generated are much lower in Hydraulic Brakes than in Mechanical Brakes.

- They are more wear-resistant. Hence, improving the advantages of hydraulic brakes.

Disadvantages

- There is always a possibility of oil/fluid leakage which can render the system inoperative or compromise the friction surfaces.

- Extreme heat may cause the fluid to boil, forming gas bubbles that compress and can’t transmit pressure effectively.

- Environmental factors such as moisture can deteriorate the hydraulic fluid over time and cause corrosion/failure of internal components.