A carburetor is a device that mixes air and fuel in a proper ratio(as per requirement) for the combustion process in an Internal Combustion engine. It works on the principle of pressure difference i.e. Bernoulli’s principle.

It is an essential part of the engine and sometimes it is also referred to as the heart of an engine (like the heart that pumps blood to our body). The carburetion or carburate is the process of mixing the air with fuel and then feed it to the Internal combustion Engine.

The carburetor controls the required quantity of fuel and breaks it up into minute globules. This afterward is mixed with the correct quantity of air.

The main purpose of a carburetor is to supply the required quantity of petrol and air mixture. The strength must be correct as per the requirement of load conditions of the engine.

Carburetors were widely used in automobile industries in earlier times but time changed and with the implementation of new technologies, the carburetor is mostly discontinued. However, they are still used on small engines like commuter motorcycles, lawn movers, and other equipment.

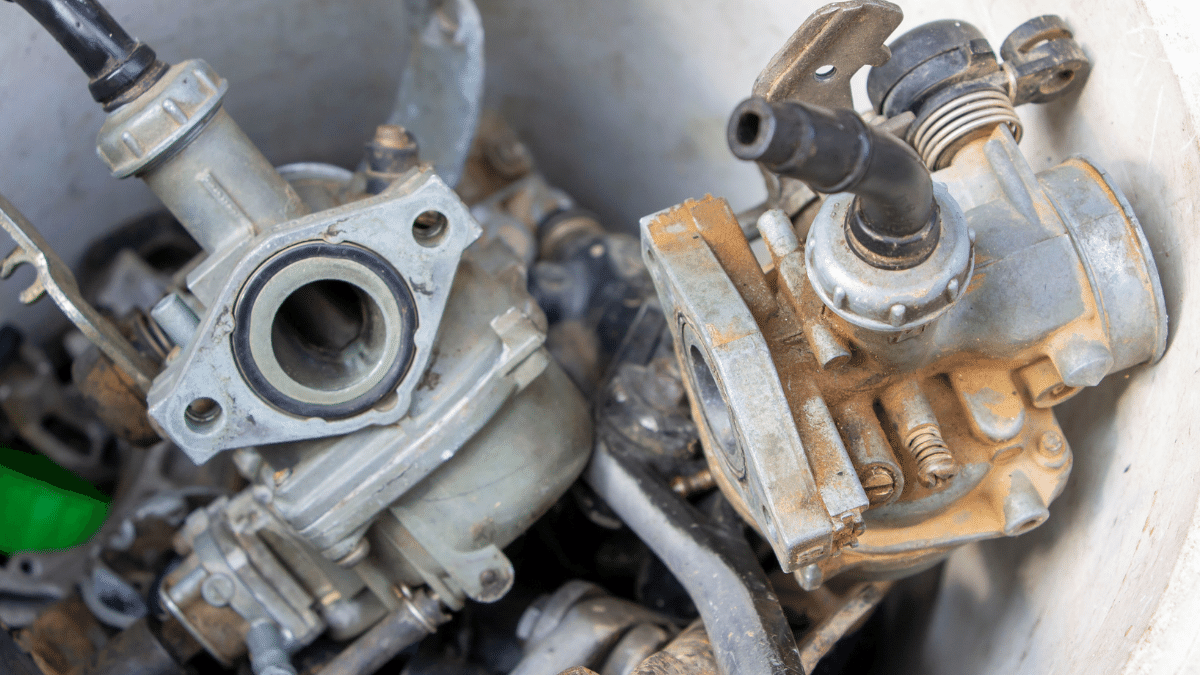

Construction of a Carburetor

- A simple carburetor consists of a venturi and a fuel jet located therein. For maintaining the level of fuel in the jet, a float chamber is also required.

- A throttle valve in the form of a flat circular metal disc mounted on a spindle. This is provided for controlling the flow of air-fuel mixture to the induction manifold. A rotary type valve also can be used instead of a disc type. The level of fuel is just kept slightly below the top of the jet to prevent leakage when not in operation. Normally 1.5 mm difference is kept between the top of the jet and the surface of the fuel in the float chamber.

- Also, there are 2 screws, one is for setting the air-fuel mixture and another one is used to set the idle speed of the engine also that is also known as the idle screw.

- A choke that restricts airflow into the carburetor causes extra fuel to be drawn. Thus creating a Richer Air/Fuel Ratio, which is necessary for an engine cold start.

Types of Carburetors

There are basically three types namely

- Vertical or up drought

- Inverted or down drought

- Horizontal drought

Working

The carburetor combines fuel and air in the engine by using an intake vacuum supply (suction created inside the cylinder during intake stroke).

The air is pulled down by the intake vacuum to the carburetor passing through the venturi. This increased velocity creates a low-pressure area due to which the fuel flows from fuel blow into the venturi through a passage. Then it moves into the airflow where it atomizes and makes an air/fuel charge. From here, the fuel and air form a combustible mixture that powers the engine.

At high engine speeds, fuel is pulled through the metering jets into the narrowest part of the carburetor throat. It then travels down to the intake manifold where it is burned to produce power in the cylinder/cylinders (if multiple).

Running lean is a condition caused when there is not enough fuel in the mixture. This can cause damage to the engine and your vehicle will not run at all.

Running rich is the condition caused if there is too much fuel. The engine can flood and run poorly. It leads to bad fuel economy due to which you can see smoke coming out through the exhaust valve.

However, these both problems can be rectified by achieving optimum tuning (correct air /fuel mixture). It can be done by adjusting it through the A/F screw.

As the throttle continues to open to obtain normal driving speed and the Venturi is exposed to vacuum, fuel flows. When the throttle is opened completely or if the engine is under a “Load”, the vacuum will drop, which allows a spring-loaded valve to open and more fuel to flow to give power and prevent “Detonation”. The carburetor plays an important part in keeping your vehicle in smooth operating condition.

Applications

- Earlier used in cars, Bikes(almost all).

- Commuter bikes(50-125 cc), lawn-movers,etc.

Advantages

- Simple design.

- Cheaper to manufacture.

- Easy to service and repair, if doesn’t work properly.

- Spares are easily available.

- Any roadside mechanic can fix all types of carburetor problems.

- Cleaning the carburetor and its parts is easy.

Disadvantages

- Cannot provide a perfect air-fuel ratio consistently.

- If not serviced for a long time the vehicle will give problems. The problems may be engine stalling, low fuel efficiency, rough idling, not starting in a single self/ kick, etc.

- Needs to be serviced after a period of time.

- Fuel wastage cannot be controlled.

- No future in automobiles.

Popular manufacturers of Carburetors

Here are some of the most popular manufacturers that manufacture carburetors are:

- Keihin,

- Mikuni,

- Hitachi,

- Solex,

- Weber,

- Zenith, etc.

Future of Carburetors

Carburetors that were widely used before the 1990s are now being replaced by a more efficient component called Fuel Injectors or FI. It is electronically controlled by ECU. Nowadays, a car doesn’t use a carburetor to power its engine. In the era of BS6 and strict pollution norms, carburetors have been fully replaced by FI in the automobile industry. Even a 97cc engine bike uses a fuel injection system. But carburetor may continue to power other applications like lawn-movers, etc.