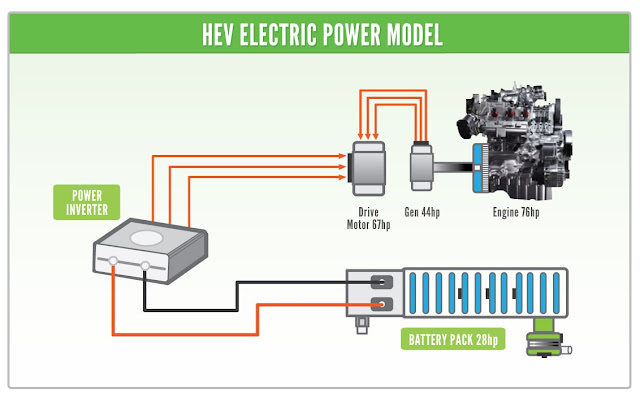

An electric vehicle or EV is a type of vehicle which uses one or more electric motors for propulsion. It may be powered through a collector system by electricity from off-vehicle sources or may be self-contained with a battery or an electric generator to convert fuel to electricity. Tesla is going to launch Electric Vehicles in India.

An electric vehicle or car is powered by an electric motor instead of an Internal combustion engine. The electric motor gets energy from a controller, which regulates the amount of power based on the driver’s use of an accelerator pedal. The electric car uses energy stored in its rechargeable batteries, which are recharged by common electricity.

Unlike a hybrid car which is powered by fuel (petrol/diesel) and uses a battery and motor to improve efficiency, an electric car is powered only and only by electricity/electric power.

Construction of Electric Vehicle:

An electric vehicle consists of following main parts:

- Electric traction motor: It is the main component of EV. Traction motor helps in propulsion of vehicle. This traction motor makes required torque and then transmit it to the wheels to further move the vehicle.

- Battery: It is the key component of EV. Main purpose is to store energy in the form of electric energy by the means of charging. It helps in switching on the vehicle and putting it on standby. It acts like a fuel tank seen in a conventional car. These batteries are designed with high ampere-hour capacity. This battery consists of a number of cells.

- On-board Charger: We use it to charge the traction battery. The function of on board charger is to adjust the DC voltage to the levels required by the battery.

- Transmission: Typically it (EV) doesn’t need one. This is so because Electric motors create torque throughout the RPM range. They can create a large amount of torque from 0 RPM almost all the way through to their maximum RPM. Since almost the entire RPM range for the motor produces usable torque, there’s no need for a transmission.

- Cooling System(Thermal cooling): In practical there are two types of cooling system available:

A). Air Cooling

Air cooling involves the passage of air along the surface of the batteries in order to absorb the heat and carry it away from the site, thereby cooling it. It is comparatively crude in comparison to a more complicated liquid cooling. But at the same time, it is much more simple, easy to apply, and robust. But there are various downsides too. The system is not very efficient in carrying the heat away as air can absorb very little heat and is quite a poor conductor. Also, the cooling performance severely depends upon the ambient temperature.

B). Liquid Cooling

This cooling solution requires a liquid as a coolant which takes the heat away from the site. This is much more expensive and much more complex as compared to an air cooling solution, but it is significantly more efficient than its other counterpart. Liquid coolers possess a better thermal capacity and are quite good at carrying the heat away. Their thermal capacities exceed that of air cooling systems. The downsides are, that they are prone to leakages, higher installation and maintenance costs.

Working of Electric Vehicle

Electric car working is not as complicated as internal combustion engine cars.

As the driver presses the accelerator, it requests torque from the electric motor. The vehicle control unit which is an integrated circuit decides how much current must be drawn from the battery. Firstly, the current is drawn from the battery. Then it is supplied to the traction motor for generating the required torque. Then battery supplies power to the motor through the power converter. The power converter will be an inverter if the electric machine is an induction motor. Finally, the transmission of this generated power helps in the motion of the vehicle through wheels.

In an electric car, the energy flows as shown below.

Battery → Inverter (power converter) → Motor → Wheel

Applications of Electric vehicle

- Small application also includes golf carts,etc.

- Vehicle types include: plug-in Electric vehicle, hybrid Evs, rail-borne EV, electrically powered spacecraft.

- In future electric vehicle will become an application in most of the segment like electric 2 wheeler, electric 3 wheeler, electric 4 wheeler, electric trucks and more.

Advantages

- Simplicity in design. No issues of balancing of rotating and reciprocating masses as compared to IC Engines.

- Electric vehicles have good power (induction motor) to weight ratio.

- Instant torque right away from 0 to the maximum limit. Peak torque at zero rpm. The moving power is immense giving the G-force pulling you to the seat.

- Regenerative braking system maximizing efficiency whilst braking.

- Typically no requirement of transmission.

- EV has no tailpipe. Hence zero tailpipe emissions.

- Silent operation as compared to a conventional vehicle.

- Efficiency is about 3 times higher than IC Engine vehicles.

- Cheaper to use and maintain.

- No or Less use of Carburetor in Vehicles.

Disadvantages

- If the battery is faulty/ has problems/ needs to be replaced. An EV battery is very expensive than a conventional one.

- Battery charging may take at-least an hour that too on quick charging point, whereas full tank petrol can be filled within 5 minutes.

- Above all, Electric cars are expensive to buy. For example: Tata Nexon Diesel top model costs around 12.5 Lakhs, the same Nexon EV costs over 15 lakhs.

- The operation of electric cars are widely based on location. The main problem is charging station which provides electricity in emergency case. It’s not readily available at all the place like petrol pump which comes at-least every 5, 10 or 15 km – that is, of course, attributed to the underdeveloped infrastructure.

- Electric vehicle may have shorter range than Internal combustion engine car. As said electric vehicle of same segment may have a range of 200-250 km. Whereas Internal combustion engine car may have a range of approx 600-700 km (with full tank).

- Charging points still a miss. There are not enough charging points which is a problem for people who frequently goes on long drive.

Leave a Reply

View Comments